INTRODUCING

CONCAVE SERIES

The name says it all, this series is all about the concave profile. Elegant, modern styles that feature deep concave faces.

MAGIC

DYNASTY

TOSCANI

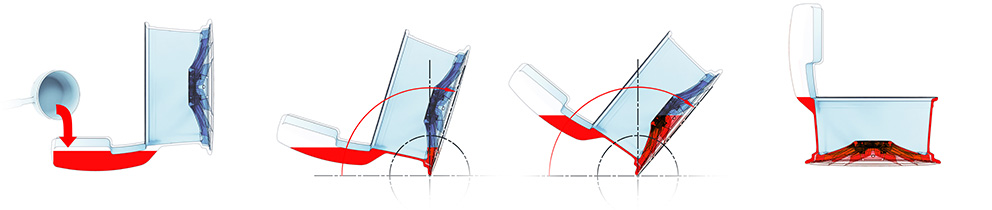

TILT CASTING TECHNOLOGY

In tilt casting, the metal is poured into a holding cup while the mold is in its horizontal position. With a preset cycle time, the casting machine raises the wheel to a vertical position, allowing the metal to enter the cavity at a slow and continuous pour rate. We utilize the tilt-pour method because of it’s feed/gate flexibility which allows for a wide variety of casting shapes.